When it comes to precision cutting in various industries, a tool that often takes the center stage is the cutting disc. Whether you're a DIY enthusiast or a professional tradesperson, understanding the types of cutting discs, their features, applications, and some frequently asked questions can greatly enhance your knowledge and skillset. In this guide, we'll delve into the world of cutting discs and provide you with the insights you need.

What is a Cutting Disc?

A cutting disc, also known as a cutoff wheel or cutting wheel, is a thin, flat, and circular tool designed for precise cutting of various materials. It typically consists of abrasive particles embedded in a binder material, which can be resin, ceramic, or a combination of both. The abrasive particles give the cutting disc its cutting power, allowing it to efficiently cut through materials with minimal friction and heat buildup.

Power Tools that Use Cutting Discs

Cutting discs are commonly used with power tools that provide the necessary speed and control for accurate cutting. Some of the power tools that use cutting discs include:

- Angle Grinders: Angle grinders are versatile handheld tools used for cutting, grinding, and polishing. They are widely used in construction, metalworking, and woodworking industries.

- Chop Saws: Chop saws, also known as cutoff saws, are stationary power tools used for making straight and precise cuts in metal, plastic, and other materials.

- Circular Saws: Circular saws equipped with cutting discs are used for cutting through materials like wood, metal, and masonry, making them a staple in carpentry and construction.

- Die Grinders: Die grinders are compact rotary tools used for grinding, sanding, and cutting tasks, especially in hard-to-reach areas.

Cutting Disc Features

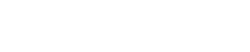

Cutting discs come in various sizes, thicknesses, and materials, each designed for specific tasks. Some common features to consider when choosing a cutting disc include:

- Diameter: Different diameters are available to match the size of your power tool and the depth of cut required.

- Thickness: Thinner discs are suitable for finer cuts, while thicker discs are more robust and offer longer durability.

- Material Compatibility: Ensure the cutting disc is designed for the material you intend to cut. Different abrasive compositions are optimized for cutting metals, masonry, ceramics, and more.

- Speed Rating: Cutting discs have a maximum RPM (revolutions per minute) rating. Always use a disc that matches or exceeds the RPM of your power tool.

- Reinforcement: Some cutting discs come with reinforced materials like fiberglass to enhance safety and durability.

Materials that can be Cut with a Cutting Disc

Cutting discs are designed to cut a wide range of materials, including:

- Metal: Steel, stainless steel, aluminum, and other non-ferrous metals.

- Masonry: Concrete, brick, stone, and other masonry materials.

- Wood: Various types of wood, including plywood and hardwood.

- Plastic: Different types of plastics and composite materials.

Types of Cutting Discs

Cutting discs, also known as cutoff wheels or cutting wheels, come in various types, each designed for specific materials and applications. Here are some common types of cutting discs:

- Metal Cutting Discs: These discs are designed specifically for cutting various types of metals, including steel, stainless steel, aluminum, and more. They are often reinforced with materials like fiberglass to provide stability and prevent breakage during high-speed cutting.

- Masonry Cutting Discs:Masonry cutting discs are suitable for cutting through hard materials like concrete, brick, stone, and ceramic tiles. They have a more abrasive composition to handle the hardness of these materials.

- Stone Cutting Discs: Similar to masonry discs, stone cutting discs are specifically formulated to cut through natural and engineered stone materials. They offer precision cutting without causing excessive damage or chipping to the stone surface.

- Tile Cutting Discs: These discs are designed for cutting ceramic and porcelain tiles. They provide clean and accurate cuts to ensure proper tile fitting during installations.

- Wood Cutting Discs: Wood cutting discs are often used with circular saws or angle grinders to cut through wood, plywood, and other wood-based materials. They have specialized teeth or abrasive coatings to efficiently cut wood fibers.

- Plastic Cutting Discs: These discs are suitable for cutting various types of plastics, such as PVC, acrylic, and polycarbonate. They prevent melting and minimize chipping, ensuring a clean and smooth cut.

- Diamond Cutting Discs: Diamond cutting discs are highly versatile and can cut through a wide range of materials, including metals, masonry, stone, tiles, and even glass. They are embedded with diamond grit, which provides exceptional cutting power and durability.

- Multi-Purpose Cutting Discs: Some cutting discs are designed to handle multiple materials, offering a balance between versatility and efficiency. They are often used when you need to cut different materials within a single project.

- Super Thin Cutting Discs: These discs are ultra-thin and are designed for precision cutting. They produce minimal waste and heat, making them suitable for delicate materials and tasks that require fine detailing.

- Abrasive Cut-Off Wheels: These general-purpose cutting discs are used for cutting and shaping various materials. They are commonly used in metalworking and fabrication.

How to Choose the Right Cutting Blade and the Make a Precision Cut?

Choosing the right cutting blade and making precision cuts are essential skills for achieving accurate and professional results in your cutting projects. Here's a step-by-step guide to help you choose the right cutting blade and make precision cuts:

Choosing the Right Cutting Blade:

- Identify the Material: Determine the type of material you need to cut, whether it's metal, masonry, wood, plastic, or another material. Different cutting blades are designed for specific materials.

- Select the Blade Type: Based on the material, choose the appropriate type of cutting blade. For example, if you're cutting metal, use a metal cutting blade; for masonry, use a masonry cutting blade, and so on. Consider

- Blade Size: Choose a blade size that matches the size of your power tool. Using the correct size ensures proper fit and safety during cutting.

- Check Arbor Size: The arbor size (hole in the center of the blade) should match the arbor size of your power tool. An incorrect arbor size can lead to instability and unsafe operation.

- Quality Matters: Invest in high-quality cutting blades from reputable brands. Quality blades not only provide better results but also last longer and enhance safety.

Making Precision Cuts:

- Mark Your Cut: Measure and mark the area you need to cut. Use a straight edge or a guide if necessary to ensure accurate markings.

- Wear Safety Gear: Put on appropriate safety gear, including safety glasses, hearing protection, and gloves, to protect yourself from debris and potential hazards.

- Secure the Workpiece: Ensure your workpiece is securely clamped or held in place to prevent movement during cutting.

- Set the Cutting Depth: Adjust the cutting depth of your power tool according to the thickness of the material. It's generally advisable to set the cutting depth slightly deeper than the material thickness.

- Position the Blade: Position the blade at the starting point of the cut, aligning it with your marked line.

- Start the Cut: Turn on the power tool and let the blade reach its full speed before beginning the cut. Apply gentle and steady pressure on the tool, allowing the blade to do the cutting. Avoid forcing the blade, as it can lead to overheating and premature wear.

- Follow the Line: Guide the tool along the marked line with a smooth and controlled motion. Keep the tool steady and maintain a consistent pace.

- Monitor Progress: Keep an eye on the cutting progress, ensuring that the blade stays on the marked line. Adjust your grip and pressure as needed to maintain control.

- Finish the Cut: Once the cut is complete, release the power trigger and wait for the blade to come to a complete stop before setting the tool down.

- Inspect and Deburr: After the cut, inspect the edges for accuracy and smoothness. Use sandpaper or a deburring tool to remove any sharp edges or burrs.

N-Durance's Best Selling Cutting Discs

N-Durance Metal Cutting Disc 305 x 3 x 20mm

Experience the next level of cutting efficiency with the N-Durance Metal Cutting Disc in the 305 x 3 x 20mm dimension. Crafted to deliver unparalleled performance, this cutting-edge tool is designed to redefine your cutting experience. With its precise engineering and top-notch materials, the N-Durance Metal Cutting Disc offers exceptional durability and superior cutting power. Whether you're working on metal, masonry, or other materials, this cutting disc is your reliable partner for achieving clean, accurate cuts every time. Elevate your craftsmanship and take on your projects with confidence using the N-Durance Metal Cutting Disc.

DA018 Features

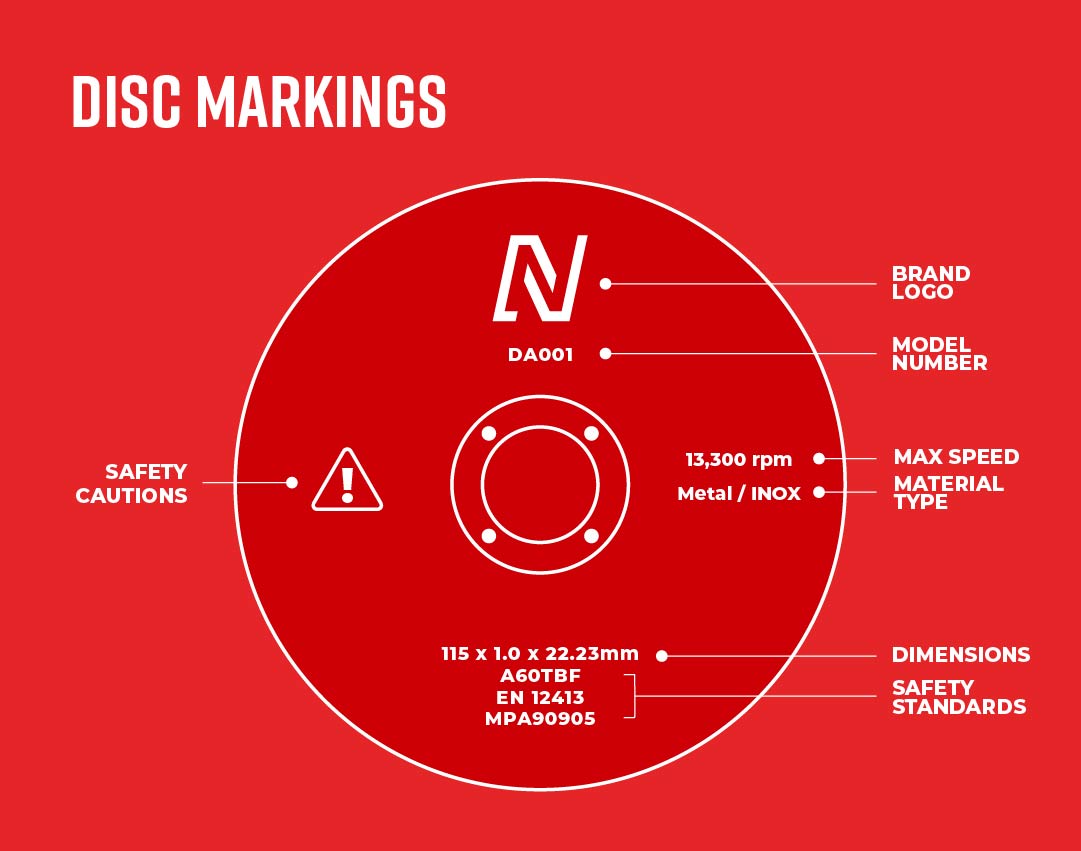

- Professional Quality, super thin, general purpose 305mm flat centre Metal Cutting Disc.

- Made of top-grade aluminium oxide ideal for fast, clean, precision cutting.

- Capable of cutting all metals including stainless steel.

- Manufactured to EN12413 standards.

DA018 Specification

- Disc Diameter: 305mm

- Bore Size: 20mm

- Thickness: 3mm

N-Durance DA014 Metal Cutting Discs 230 x 3.2 x 22.2mm

Engineered to redefine cutting standards, these discs boast exceptional craftsmanship and cutting-edge technology. With a focus on durability and performance, the N-Durance DA014 Metal Cutting Discs effortlessly glide through metals, offering clean, effortless cuts that elevate your projects. Crafted for professionals and DIY enthusiasts alike, these discs guarantee a seamless cutting experience. Embrace accuracy and efficiency with N-Durance DA014 Metal Cutting Discs – your gateway to superior results.

DA014 Features

- Professional Quality, super thin, general purpose 230mm flat centre Metal Cutting Disc.

- made of top-grade aluminium oxide ideal for fast, clean, precision cutting.

- Capable of cutting all metals including stainless steel.

- Manufactured to EN12413 standards.

DA014 Specification

- Disc Diameter: 230mm

- Bore Size: 22.2mm

- Thickness: 3.2mm

N-Durance Metal Cutting Disc 355 x 2.8 x 25.4mm

Experience cutting-edge innovation with the N-Durance Metal Cutting Disc in the impressive 355 x 2.8 x 25.4mm dimensions. Engineered to redefine your cutting endeavors, this disc sets a new standard for precision and efficiency. Crafted with meticulous attention to detail, it effortlessly slices through various materials, from metals to masonry, with remarkable ease. The N-Durance Metal Cutting Disc guarantees not only flawless cuts but also exceptional longevity, ensuring you stay ahead of your tasks without compromise. Elevate your projects with the N-Durance Metal Cutting Disc and embrace the true potential of cutting perfection.

DA006 Features

- Professional Quality, super thin, general purpose 75mm flat centre Metal Cutting Disc.

- Made of top-grade aluminium oxide ideal for fast, clean, precision cutting.

- Capable of cutting all metals including stainless steel.

- Manufactured to EN12413 standards.

DA006 Specification

- Blade Diameter: 75mm

- Bore Size: 0.8mm

- Thickness: 9.53mm

N-Durance DA020 Metal Cutting Disc 125 x 3 x 22.2mm

Precision-engineered to redefine cutting efficiency, this disc is a game-changer for all your cutting needs. With its sleek design and superior technology, the N-Durance DA020 effortlessly slices through metal and more, delivering clean and accurate cuts with every use. Whether you're a professional or a DIY enthusiast, this cutting disc promises reliability and durability, making your tasks smoother and more enjoyable. Embrace the future of cutting with the N-Durance DA020 Metal Cutting Disc and experience the pinnacle of performance firsthand.

DA020 Features

- Professional Quality, super thin, general purpose 125mm flat centre Metal Cutting Disc.

- Made of top-grade aluminium oxide ideal for fast, clean, precision cutting.

- Capable of cutting all metals including stainless steel.

- Manufactured to EN12413 standards.

DA020 Specification

- Cutting Disc. Grade A30S4BF.

- 3.0mm Thick

- Blade Diameter: 125mm

- Bore Size: 22.2mm

N-Durance DA013 Super Thin Metal Cutting Disc 230 x 1.6 x 22.2mm

These cutting discs redefine the art of precision cutting, offering an ultra-thin profile without compromising on power. Engineered with excellence in mind, the N-Durance DA013 slices through metal with unparalleled ease, providing immaculate cuts every time. Crafted for professionals who demand superior quality, this pack ensures both performance and longevity. Whether it's a single task or a bulk project, the N-Durance DA013 Super Thin Metal Cutting Discs promise precision, consistency, and remarkable value. Upgrade your cutting experience today.

DA013 Features

- Aluminium oxide

- Good quality, general purpose metal cutting blades

DA013 Specification

- Blade Diameter: 230mm

- Blade Thickness: 1.6mm

- Bore Size: 22mm

FAQs

How long do cutting discs last?

Cutting disc lifespan depends on factors like the material being cut, the disc's quality, and usage conditions. As a general guideline, discs can last anywhere from a few minutes to several hours of cutting time. It's important to replace discs when they become worn or damaged to ensure safe and efficient cutting.

Will a metal cutting disc cut stone?

Metal cutting discs are not suitable for cutting stone or masonry. Stone-cutting discs have a different abrasive composition designed to tackle the hardness and toughness of stone materials. Attempting to cut stone with a metal cutting disc could lead to premature wear or even disc failure.

Do cutting discs have an expiry date?

While cutting discs don't typically have an official expiration date, they can degrade over time due to exposure to moisture, heat, and other environmental factors. It's recommended to use cutting discs within two to three years of their manufacturing date to ensure optimal performance and safety.

In conclusion, cutting discs are indispensable tools in a wide range of industries, enabling precise and efficient cutting of various materials. By understanding the types, features, and applications of cutting discs, you can choose the right tool for your projects while maintaining safety and quality. Remember to adhere to manufacturer recommendations and safety guidelines to maximize the lifespan and performance of your cutting discs.